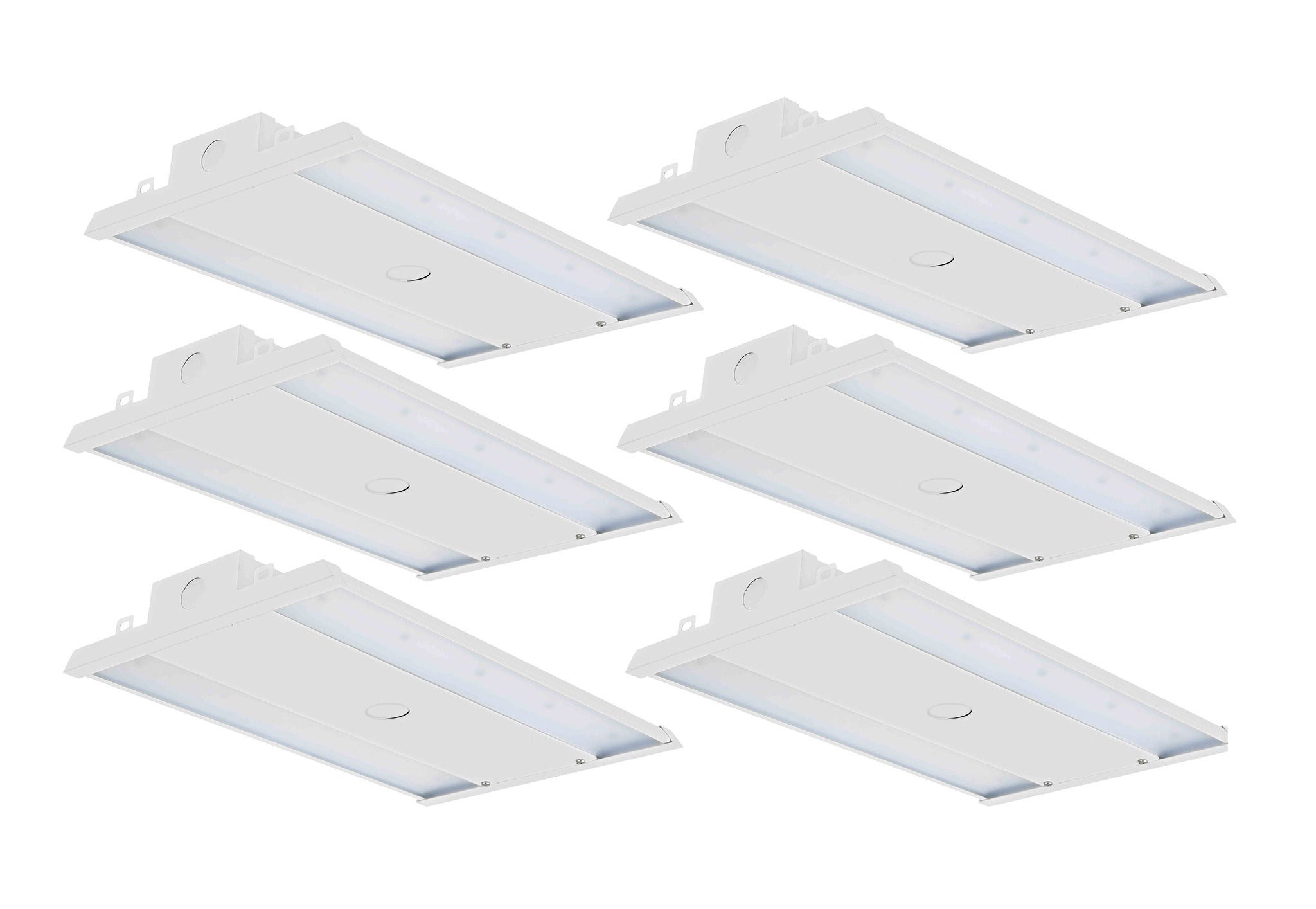

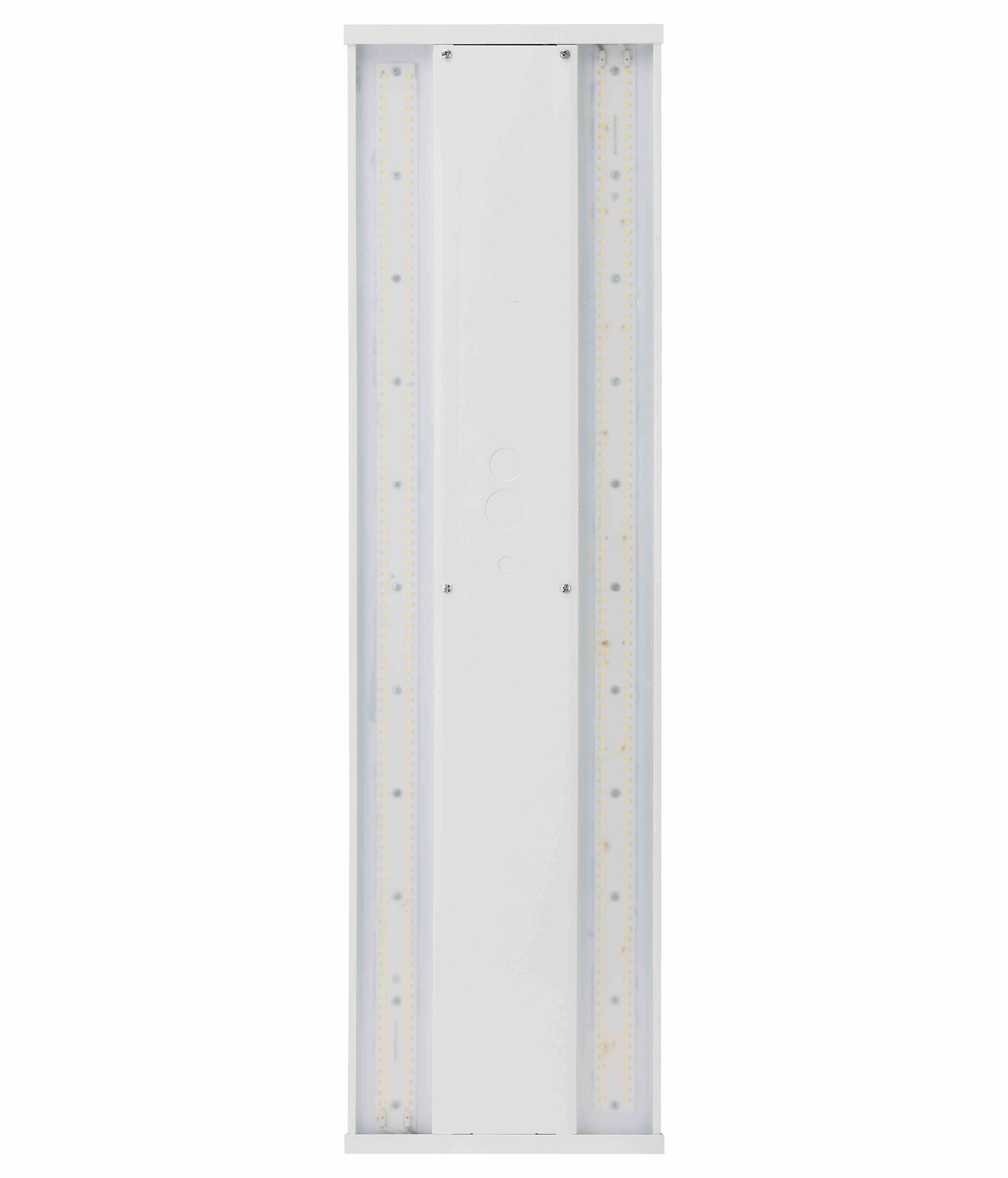

Linear High Bay-120-277V

-

Illuminate vast spaces with our cutting-edge Linear High Bay series, designed for superior performance in high-ceiling environments. at 120V-277V, ranging from 130W to 300W, these fixtures deliver exceptional brightness and uniform illumination ideal for warehouses, factories, and large retail spaces.

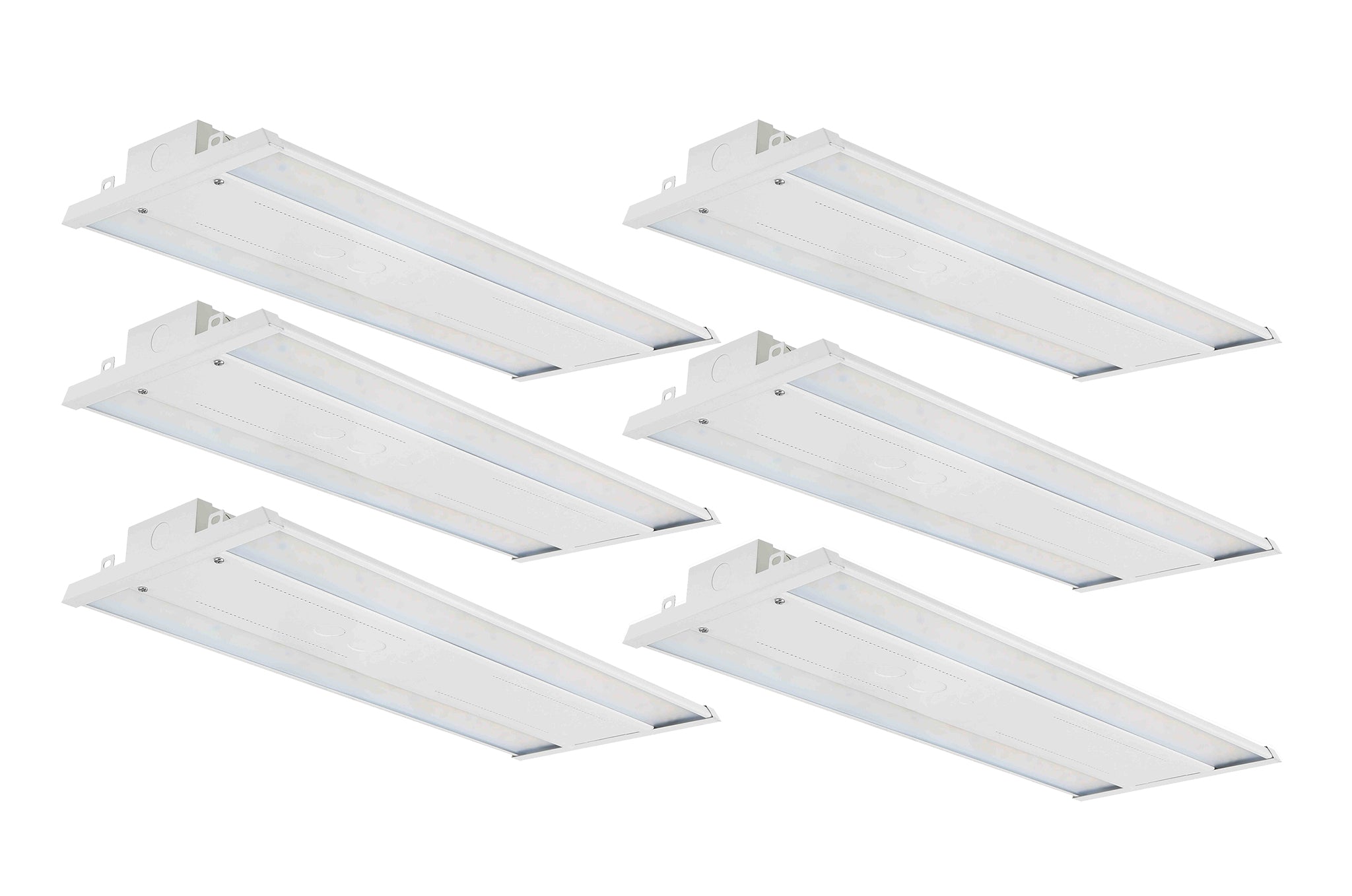

With energy efficiency up to 135 lm/W, our LED high bays significantly reduce operating costs compared to traditional lighting. Featuring durable construction, long lifespan, and versatile mounting options, these fixtures ensure minimal maintenance and maximum flexibility.

Available in multiple color temperatures and with optional sensors, our Linear High Bay series combines powerful illumination with advanced features to enhance productivity and safety in industrial and commercial settings.

Linear High Bay LED Lights: The Ultimate Guide to Smart, Efficient Industrial Lighting

In today’s industrial and commercial environments, the demand for high-efficiency, low-maintenance lighting is stronger than ever—and Linear High Bay LED Lights are stepping up to meet that challenge. Designed specifically for spaces with high ceilings like warehouses, factories, and gymnasiums, these lights combine cutting-edge LED technology with smart energy-saving features to deliver uniform brightness, long lifespans, and exceptional cost savings.

Built with durable materials such as aluminum housings and polycarbonate diffusers, linear high bay LEDs ensure superior thermal management and impact resistance, even in the harshest environments. Unlike traditional bulky fixtures, their sleek design enables flexible installation and optimized light distribution. Modern versions can also be integrated into smart lighting systems, enabling automation through motion sensors, daylight harvesting, and centralized control.

Choosing the right linear high bay light involves more than just picking a bright fixture—it requires understanding ceiling height, beam angles, voltage compatibility, and layout planning. When done right, businesses can reduce energy consumption by up to 70%, minimize downtime, and create safer, more productive spaces. In this guide, we explore how linear high bay LED lights work, what materials make them durable, common installation mistakes, and how smart lighting systems maximize ROI.

1. What Are Linear High Bay LED Lights?

Linear high bay LED lights are specialized lighting fixtures designed for large, high-ceiling spaces such as warehouses, factories, gymnasiums, and retail stores. Unlike traditional high bay lights, which often use bulky reflectors, linear high bay LEDs feature a sleek, elongated design that provides uniform illumination with minimal glare.

These fixtures utilize advanced LED technology to deliver high lumen output while consuming significantly less energy than metal halide or fluorescent alternatives. Their modular design allows for flexible installation, either suspended or surface-mounted, making them ideal for industrial and commercial environments where bright, consistent lighting is crucial.

Key characteristics include:

High efficiency – Lower energy consumption with superior light output.

Long lifespan – Typically rated for 50,000 to 100,000 hours of operation.

Durability – Built to withstand harsh conditions like dust, moisture, and vibrations.

Customizable lengths – Available in various sizes to fit different ceiling heights and layouts.

2. Why Materials Matter in Linear High Bay LED Lights

The performance and durability of linear high bay LED lights heavily depend on the materials used in their construction. Here’s how different components impact quality:

Housing & Heat Sink

Aluminum – The most common material due to its excellent heat dissipation properties, which prolongs LED life.

Polycarbonate – Used for diffusers or covers, offering impact resistance and optical clarity.

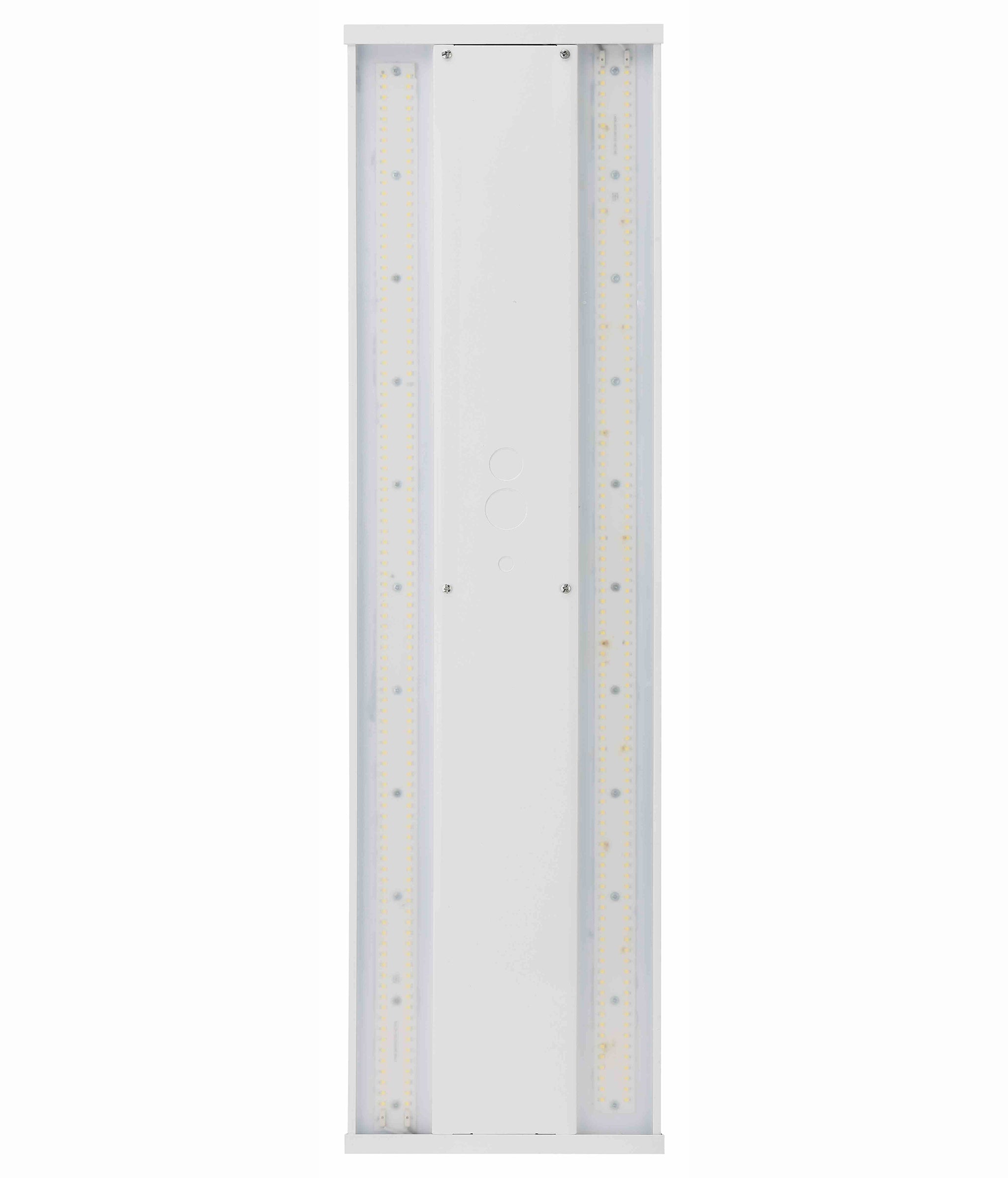

LED Chips & Drivers

High-quality LEDs (e.g., Samsung, Osram, Cree) – Ensure consistent brightness and color accuracy.

Constant current drivers – Prevent flickering and extend lifespan by regulating power efficiently.

Optics & Reflectors

PMMA (acrylic) lenses – Provide precise beam control and reduce light waste.

Anodized reflectors – Enhance light distribution while resisting corrosion.

Choosing fixtures with robust materials ensures better thermal management, energy efficiency, and resistance to industrial wear and tear.

3. How Linear High Bay LED Lights Work: Key Components

Understanding the technology behind linear high bay LEDs helps in selecting the right fixture. Here’s a breakdown of their core functionalities:

Step 1: Power Regulation with Constant Current Drivers

Converts AC power to a stable DC output.

Maintains consistent brightness and prevents voltage fluctuations.

Step 2: Thermal Management

Heat sinks and ventilation channels dissipate excess heat.

Prevents overheating, which can degrade LED chips over time.

Step 3: Light Distribution

Symmetrical optics – Ideal for general area lighting.

Asymmetrical optics – Directs light sideways for aisle or task lighting.

Reflective coatings – Maximize lumen output by minimizing absorption.

4. What Are the Most Common Mistakes When Selecting or Installing High Bay Lighting?

Choosing and installing linear high bay LED lights may seem straightforward, but even small errors can lead to poor performance, higher costs, or safety risks. Here are the most frequent mistakes to avoid:

Mistake1: Ignoring Ceiling Height & Light Spread

Problem: Using fixtures with incorrect beam angles or insufficient lumen output for the space.

Solution:

- For ceilings < 20 ft, use wide-beam (120°) fixtures.

- For 20–30 ft, opt for medium-beam (90°).

- For > 30 ft, choose narrow-beam (60° or less) for focused illumination.

Mistake2: Overlooking Thermal Management

Problem: Poor heat dissipation shortens LED lifespan.

Solution:

- Select fixtures with aluminum heat sinks and ventilation design.

- Avoid installing in enclosed fixtures unless rated for it.

Mistake3: Incorrect Wiring & Voltage Compatibility

Problem: Flickering or premature failure due to incompatible drivers.

Solution:

- Verify if the fixture supports 120V, 277V, or 480V.

- Use constant current drivers for stable performance.

Mistake4: Improper Spacing & Layout Planning

Problem: Uneven lighting with dark spots or excessive brightness in some areas.

Solution:

- Follow the 1:1 height-to-spacing ratio (e.g., if mounted at 25 ft, space fixtures 25 ft apart).

- Use lighting simulation software for large spaces.

By avoiding these mistakes, you ensure optimal efficiency, longevity, and light distribution.

5. Why Smart Lighting Systems Are Beneficial for Commercial & Industrial Spaces

Smart linear high bay LED lighting goes beyond basic illumination—it enhances efficiency, control, and cost savings. Here’s why businesses are upgrading:

Energy Savings & Automated Controls

Motion sensors turn off lights in unoccupied areas.

Daylight harvesting adjusts brightness based on natural light.

Scheduled dimming reduces power usage during off-peak hours.

Remote Monitoring & Maintenance Alerts

Real-time energy usage tracking via cloud-based systems.

Predictive maintenance alerts for failing drivers or LEDs.

Centralized control for large facilities (no manual switching).

Improved Safety & Productivity

Emergency lighting integration during power outages.

Task-tuning capabilities (e.g., brighter light in work zones).

Reduced glare & flicker for better visual comfort.

Smart Lighting Implementation Steps

1. Audit existing lighting (wattage, placement, usage patterns).

2. Choose compatible smart fixtures (Zigbee, DALI, or Bluetooth-enabled).

3. Install sensors & gateways for automation.

4. Train staff on control systems (mobile app/dashboard).

With smart lighting, businesses cut energy costs by 30–70% while improving functionality.

Linear high bay LED lights are a smart investment for any business seeking powerful, efficient, and scalable lighting for high-ceiling environments. Their energy-saving capabilities, durable construction, and customizable design make them ideal for industrial and commercial use. By understanding their components, choosing high-quality materials, avoiding installation pitfalls, and incorporating smart controls, facilities can enjoy brighter spaces, longer fixture life, and significant cost reductions. Whether you're retrofitting an old system or designing a new facility, linear high bay LED lighting offers a reliable path to smarter illumination.