LED Tube lights

There are 3 categories for our LED tube lights. They are T8 LED tube lights, Integrated tube lights, and freezer lights (cooler lights).

-

T8 LED tube lights are plug in fixtures. The most common LED T8 tube lights are 2ft 2pin tube lights, 4ft 2pin tube lights, 8ft single pin tube lights, 8ft R17D tube lights. T8 LED tube lights are used to replace the traditional fluorescent tube lights inside the 2x2, 2x4 or 1x4 Troffer fixtures that sit on T-bar ceiling in locations like offices, school, etc.

-

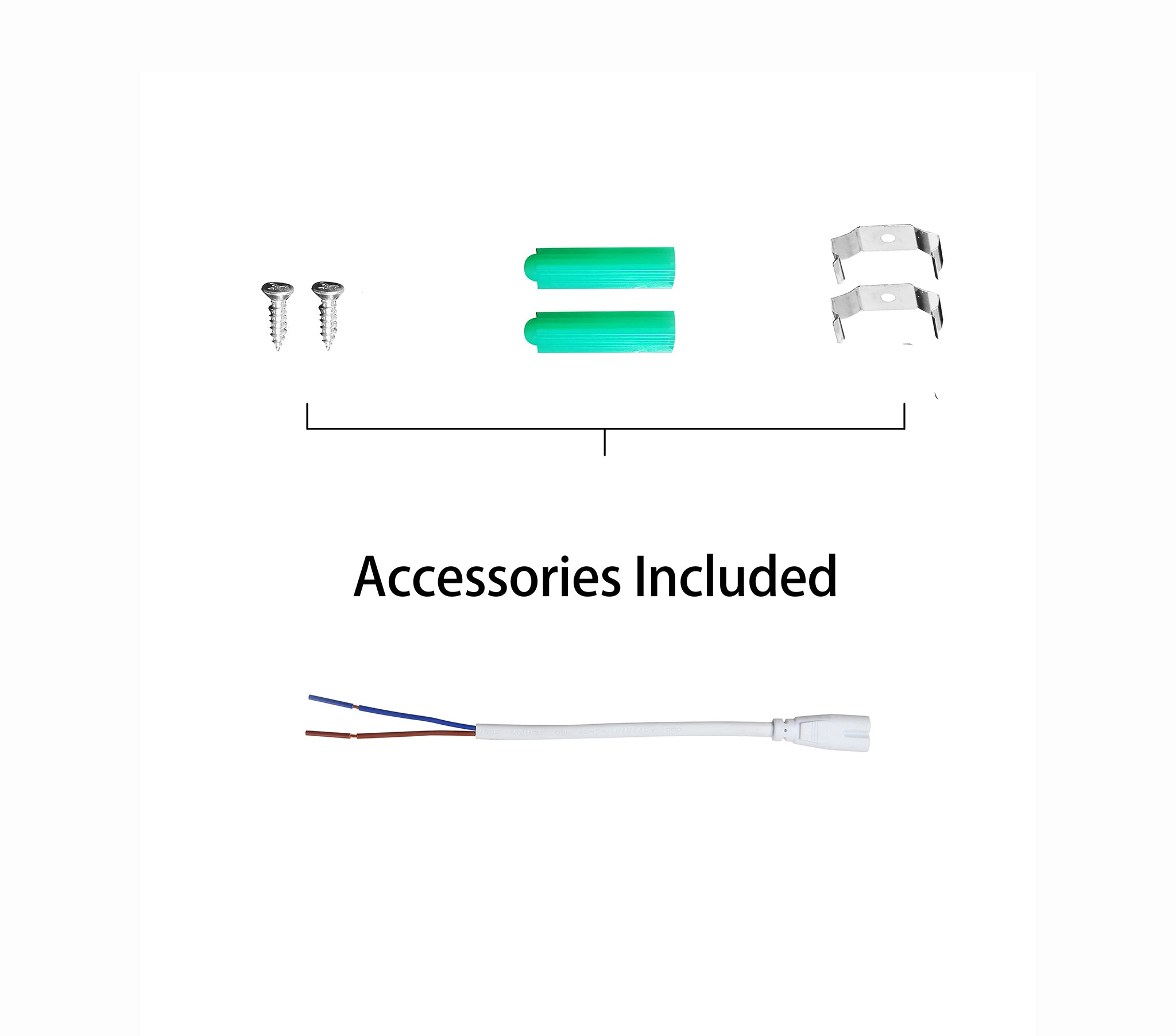

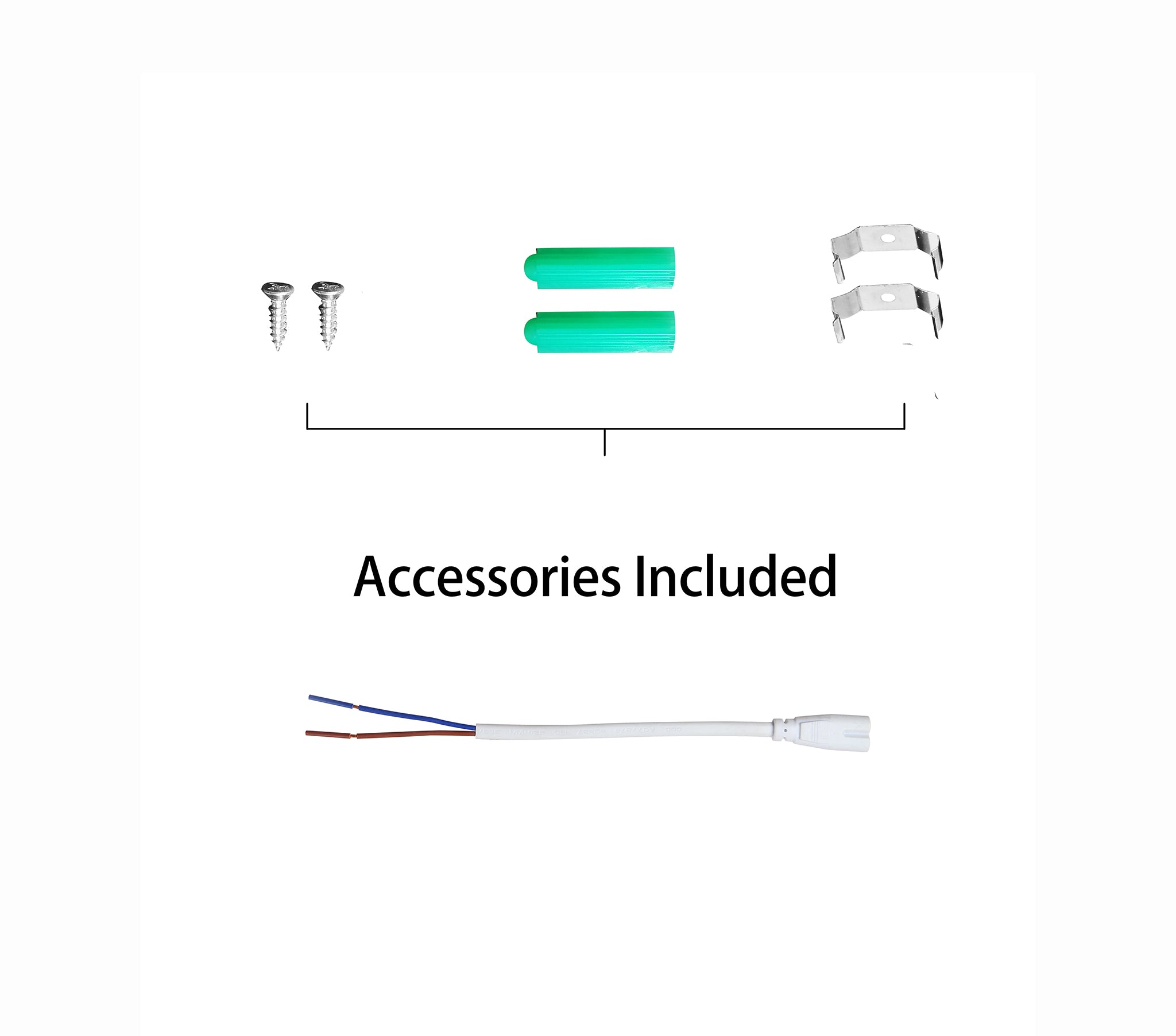

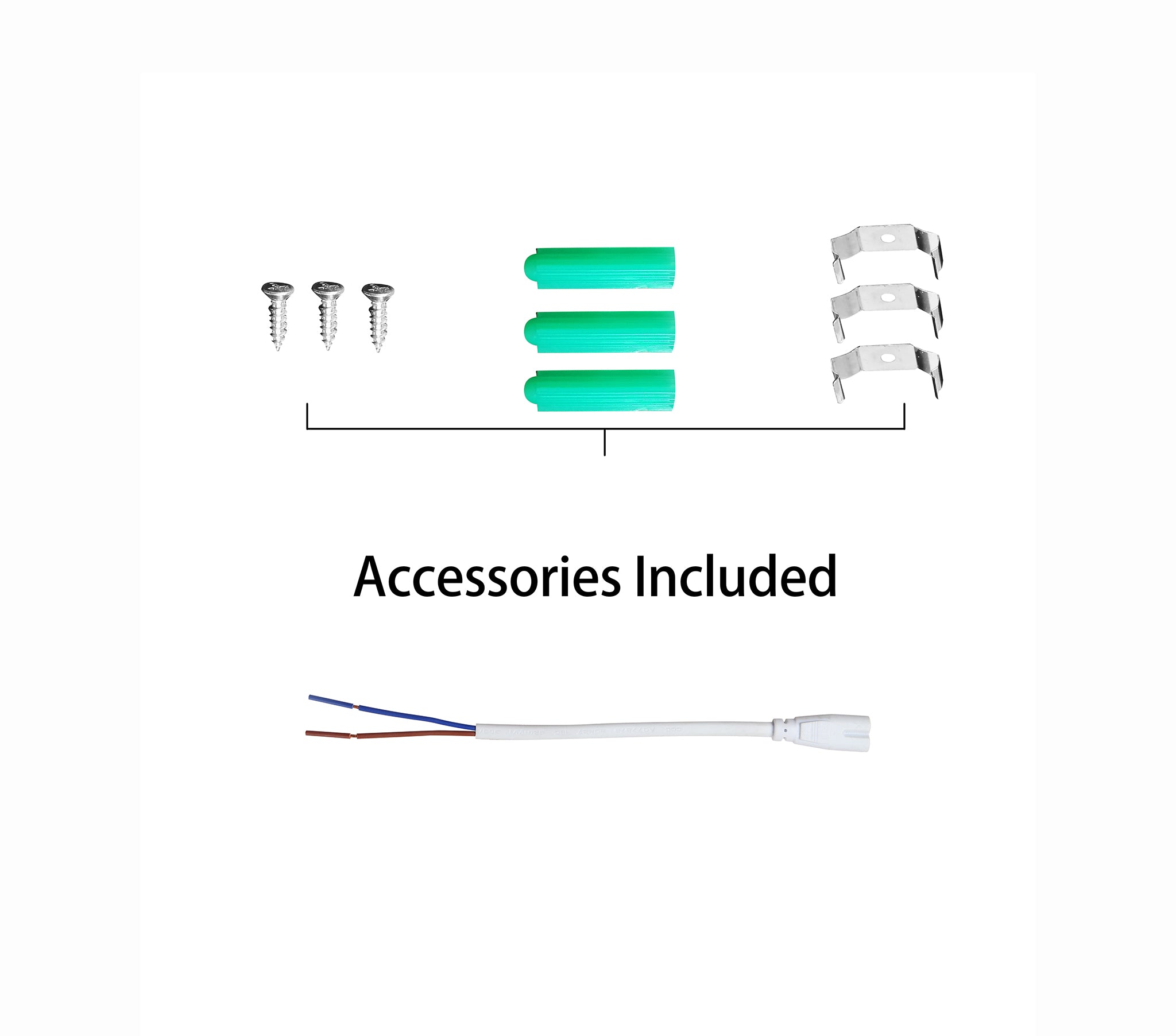

Integrated tube fixtures are all-in-one LED shop light fixtures. They are surface mounted. The most common sizes of integrated shop light fixtures are 2ft, 4ft and 8ft. They are often used in retail stores, garages, workshop or any other indoor areas with a ceiling around 8ft to13ft. The surface mounting accessories are included for each integrated tube fixture.

-

Freezer lights/Cooler lights are used inside glass door freezers, walk in freezers/coolers. The common freezer lights/cooler lights size are 4ft, 5ft and 6ft and they are usually V-shape (2 lighting boards). The cables and mounting accessories are included in our cooler lights package.

LED Tube Light Fixture: A Smart Upgrade from Traditional Fluorescent Lighting

LED tube light fixtures have rapidly become the go-to lighting solution for homes, offices, and industrial environments—and for good reason. Unlike outdated fluorescent tubes that depend on gas discharge and mercury-filled bulbs, LED tube fixtures use advanced semiconductor technology to deliver cleaner, more energy-efficient light. They consume 40–60% less power, last over three times longer, and provide instant, flicker-free illumination.

Whether you're illuminating a kitchen, warehouse, or retail space, LED tubes offer unmatched performance. With aluminum housings for superior heat dissipation and polycarbonate diffusers for even light distribution, these fixtures are built for both functionality and durability. Options range from ballast-compatible to direct-wire installations, giving users the flexibility to upgrade existing fixtures easily.

In addition to energy savings and eco-friendliness, these fixtures also handle diverse environments—tolerating wide temperature ranges, high humidity, and voltage fluctuations. For the best results, buyers should look for quality components like isolated drivers, high CRI ratings, and certifications such as UL or ENERGY STAR.

LED tube light fixtures are more than just replacements—they're upgrades that improve lighting quality, cut costs, and enhance safety. Making the switch is a smart move for any modern space.

What Is an LED Tube Light Fixture and How Does It Differ from Traditional Lighting?

LED tube light fixtures are modern lighting solutions designed to replace conventional fluorescent tubes. Unlike traditional lighting, which relies on gas discharge and phosphor coating (e.g., T8/T12 fluorescent tubes), LED tubes use light-emitting diodes (LEDs) to produce brighter, more energy-efficient illumination.

Key Differences:

Energy Efficiency: LED tubes consume 40–60% less power than fluorescent equivalents.

Lifespan: LEDs last 30,000–50,000 hours, outperforming fluorescent tubes (10,000–15,000 hours).

Instant Start: No flickering or warm-up time, unlike traditional tubes.

Eco-Friendly: LEDs contain no mercury and emit less heat.

Compatibility: Some LED tubes require ballast bypass ("direct wire"), while others work with existing ballasts.

How an LED Tube Light Fixture Is Assembled: Step by Step

Building an LED tube fixture involves precise components and wiring. Here’s a simplified breakdown:

Materials Needed:

LED tube

Aluminum housing (heat sink)

Polycarbonate diffuser

Driver/power supply

End caps (with pins for socket connection)

Assembly Steps:

1. Prepare the Housing: Cut aluminum to size for heat dissipation.

2. Install LEDs: Mount LED chips onto a printed circuit board (PCB) and secure it inside the housing.

3. Wire the Driver: Connect the driver to the PCB to regulate voltage.

4. Attach the Diffuser: Snap the polycarbonate cover onto the housing to distribute light evenly.

5. Seal End Caps: Fix insulated end caps with electrical pins for socket compatibility.

Pro Tip: For retrofit installations, verify if the fixture requires ballast removal.

How LED Tube Light Fixtures Work: A Technical Breakdown

LED tube fixtures operate through semiconductor technology. Here’s the science behind them:

1. Power Conversion:

AC power from the mains is converted to low-voltage DC via an internal driver.

Constant current ensures stable LED performance.

2. Light Emission:

When electrons pass through the diode’s semiconductor material (e.g., gallium nitride), photons (light) are released.

Color temperature (e.g., 3000K warm white, 5000K daylight) depends on phosphor coatings.

3. Thermal Management:

Aluminum housings absorb and dissipate heat, preventing LED degradation.

Why It’s Superior: No electrodes or fragile components (unlike fluorescent tubes), reducing failure points.

Where to Use LED Tube Light Fixtures: Residential, Commercial, Industrial

LED tubes adapt to diverse settings due to their efficiency and durability:

Residential Applications

Kitchens: High-CRI tubes enhance food prep areas.

Garages: Instant brightness in cold environments.

Basements: Low-energy, long-lasting illumination.

Commercial Spaces

Offices: Flicker-free tubes reduce eye strain.

Retail Stores: Highlight products with 5000K daylight tubes.

Industrial/Outdoor Use

Warehouses: High-lumen (2200+ LM) tubes for wide coverage.

Parking Lots: Weatherproof fixtures with motion sensors.

What Are the Heat, Humidity, and Voltage Tolerance Limits of LED Tube Fixtures?

LED tube fixtures are engineered for resilience, but environmental factors impact performance. Here’s how they handle extreme conditions:

Heat Tolerance

Operating Range: Most LED tubes work in −20°C to 50°C (−4°F to 122°F).

Heat Management: Aluminum housings dissipate heat, but prolonged exposure >60°C (140°F) shortens lifespan.

Why It Matters: Excessive heat reduces LED efficiency (called *lumen depreciation*).

Humidity Resistance

IP Ratings: Look for IP65 (dustproof + water-jet resistant) for bathrooms or outdoor use.

Condensation Risk: Non-IP-rated tubes may fail in >85% humidity.

Voltage Fluctuations

Tolerance: Quality fixtures handle 100V–277V (universal voltage) or 120V–347V (industrial).

Surge Protection: Built-in drivers prevent damage from ±10% voltage spikes.

Pro Tip: For saunas or factories, opt for tubes with industrial-grade certifications (e.g., UL Damp Location).

How to Identify a High-Quality LED Tube Fixture: 5 Key Checks

Avoid cheap imitations by verifying these features:

Certifications

Safety: UL/CE/ROHS marks ensure compliance.

Performance: ENERGY STAR rating guarantees efficiency.

Component Quality

LED Chips: Brands like Cree, Nichia, or Bridgelux offer better longevity.

Driver: Isolated drivers (vs. driverless) reduce flicker.

Technical Specs

L70 Lifespan: ≥50,000 hours (means LEDs retain 70% brightness at end-of-life).

CRI: ≥80 for accurate color rendering (90+ for retail/art studios).

Build Materials

Housing: Die-cast aluminum (not plastic) for heat dissipation.

Diffuser: Polycarbonate (resists yellowing; avoid acrylic).

Warranty: Reputable brands offer 3–5 years coverage.

Common Mistakes to Avoid When Installing LED Tube Lights

Improper installation leads to premature failure. Steer clear of these errors:

Ignoring Ballast Compatibility

Myth: "All LED tubes work with existing ballasts."

Truth: Only *ballast-compatible* types do. Others require direct wiring (ballast bypass).

Overlooking Voltage

Mistake: Using 120V tubes in 277V commercial fixtures.

Fix: Verify voltage range on the label.

Poor Wiring

Risk: Loose connections cause arcing or flickering.

Step-by-Step Fix:

1. Turn off power at the breaker.

2. Use wire nuts for secure driver connections.

3. Test with a multimeter before mounting.

Incorrect Fixture Spacing

Problem: Too few tubes create dark zones.

Rule of Thumb: Space 1.5× the ceiling height (e.g., 8 ft ceiling → 12 ft between fixtures).

Skipping Thermal Paste

Why: Applying thermal paste between PCB and housing boosts heat transfer.

How to Clean and Maintain LED Tube Light Fixtures

Routine care extends lifespan by 20–30%. Follow these steps:

Monthly Dusting

Tools: Microfiber cloth or soft brush.

Method: Gently wipe diffuser and housing (avoid abrasive cleaners).

Deep Cleaning (Every 6 Months)

1. Power off the fixture.

2. Remove tubes by twisting 90° (for shunted sockets).

3. Wash diffusers with mild soap + water; dry completely.

4. Vacuum fixture interiors to remove debris.

Inspection Checklist

Flickering? Check for loose wiring or driver issues.

Dark Spots? Replace tubes showing uneven illumination.

Corrosion? In humid areas, use dielectric grease on contacts.

Warning: Never spray water directly onto fixtures unless IP65-rated.

This article explores LED tube light fixtures, detailing how they outperform traditional fluorescent tubes in efficiency, longevity, and safety. It covers their assembly, working principles, environmental tolerances, and applications in residential, commercial, and industrial settings. It also provides tips on identifying high-quality fixtures, avoiding installation mistakes, and maintaining the fixtures to extend their lifespan.